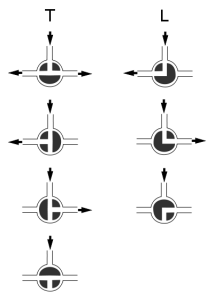

Due to its characteristics, the ball valve lends itself well to “three-way” operation. With reference to the figure we can see that the sphere, instead of having a straight rectilinear passage, has an “L” (on the right) or a “T” (on the left). In both cases, the valve connects three openings, which can be connected or not depending on the position of the valve. In this case, sometimes “half-turn” valves, or more precisely “two-quarters of a turn” are used; however, these are subject to frequent maneuvering errors. As you can see, the “T” ball valve allows all combinations (in the order, double output, left output, right output, closed), while the “L” sphere allows only right or left exit, or position closed.

There are also four-way valves, but they are a rarity and are used only as flow deflection systems and not as regulation of flow rates or pressures. Normally the four-way ball valves are used in centralized heating / air-conditioning systems to regulate the temperature of the thermo-conductive fluids by means of the appropriate actuator and control unit carrying out a proper mixing of the return fluid with the fluid in delivery to allow a regulation of the temperature of the carrier fluid. They are vaguely comparable to two “L” type sanitary ball valves and are usually called mixing valves.

Recent Comments