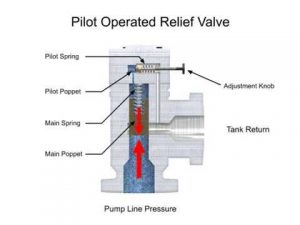

Like other pressure relief valves (PRVs), pilot-operated relief valves (PORVs) are used for emergency relief in case of overpressure (for example, a tank becomes too hot and the dilatant fluid increases the pressure to dangerous levels). The difference between conventional PORV and PRV is that pilot valves use system pressure to seal the valve. A PRV generally uses a spring to hold the disc or piston on the seat. The essential parts of a PORV are a pilot valve (or control pilot), a main valve, a pilot tube, the dome, a disc or a piston and a seat. The volume above the piston is called the dome.

PORV are also called pilot-operated safety valve (POSV), pilot-operated pressure relief valve (POPRV), or pilot-operated safety relief valve (POSRV), depending on the manufacturer and the application. Technically, POPRV is the most generic term, but PORV is often used generically (as in this article), even though it should refer to valves in liquid service.

Compared to non-piloted pressure relief valves, they have the following advantages:

- Smaller package on larger sizes of pipe.

- More options for control.

- Watertight more tightly when system pressure approaches but does not reach set pressure.

- The control driver can be mounted remotely.

- Some designs allow you to change the size of the orifice in the main sanitary relief valve.

- Can be used in engines.

Recent Comments