Sanitary pumps work very well even in the conditions of high pressure, high volume, and high temperature. More attractively, operation and maintenance of these devices are quite easy. Many companies offer some additional facilities as well. For example, you can get sanitary pumps with the ability to check the unintended operation of the valve. To get an idea of which way the water is moving, you may ask for directional nameplates.

When making a buying decision, pay as more attention as possible to the trouble-free and safe operation. That is why the total system design should be considered so that no problem occurs in the future. If you need one for a specific purpose then choose a special or custom valve instead of a ready-made valve. Some of the points to keep in mind are low operating torque, maximum flow design, panel mounting, two or three-way flow models, leak-tight seal in extreme pressure conditions and availability of electric and pneumatic actuators.

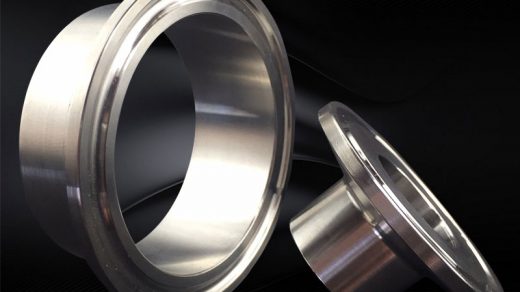

Manufacturers of sanitary pumps use different material according to the requirement of the application. Some of the examples include brass, carbon steel, stainless steel and dome special alloys besides alloy 400. Temperature adjustment capacity ranges between 65 degrees and 850 degrees Fahrenheit. Some products are available with a working pressure of up to fifteen thousand psig. Similarly, flow coefficient can go up to 130. However, if you feel that products available in the market are not able to meet your specific needs, contact the supplier and discuss with them to check their ability of customization. Remember, be professional and order in bulk.

Not all sanitary pumps are the same therefore if you are shopping for some you should do so in consideration of the types of fluids that will go through them and the contents of the pumps’ materials. Different pumps are made of different materials to be used in different applications. You should, therefore, choose correctly in accordance to your requirements.

Recent Comments